An industrial plant consists of many different structural parts such as beams, columns, nuts and bolts, and of functional parts such as pipelines, valves, and insulation. These all have different ways of deteriorating and impacting the safety and correct functioning of the plant. To guarantee safety and maintain robust production, industrial plants have to undergo elaborate visual inspections, which require experienced and certified personnel.

The most straightforward way to do these inspections is to put scaffolding around the plant and inspect all parts manually. This process is very time consuming and can take months before the inspection is complete. A better way is to capture images of the entire facility using drone and panoramic imagery which allows better assessment afterwards. However, inspectors assessing these images manually can still take up to 10 minutes per image. Additionally, they will suffer from fatigue after doing inspections for some time and will miss important defects.

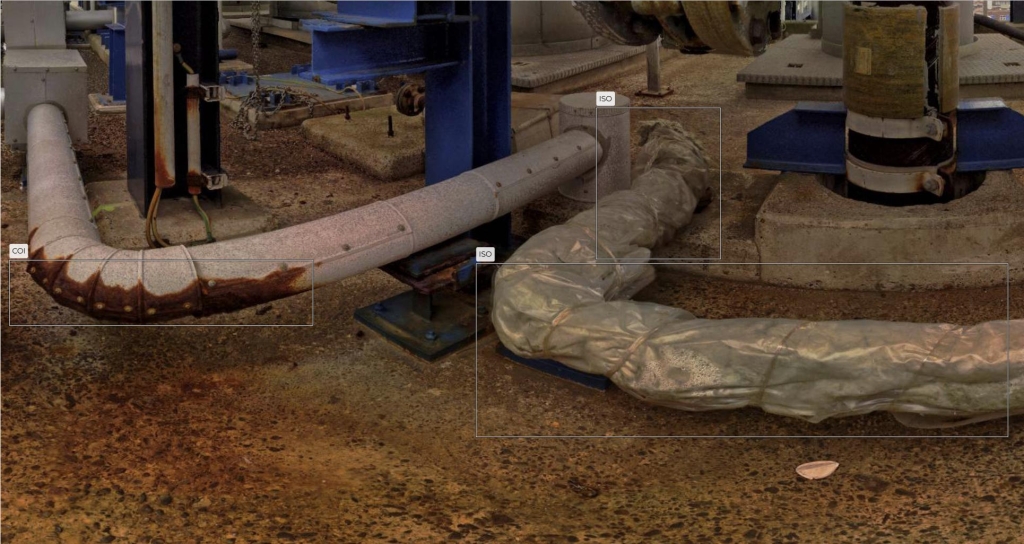

Using our platform, the inspection time can be reduced to mere minutes, which results in huge cost savings as the required hours per inspector is reduced dramatically. Next to that, our inspection models does not suffer from fatigue and will spot defects the inspector would otherwise have missed. It assists inspection experts in finding all the relevant defects in any plant. We have trained models that can detect different corrosion types and damage to insulation, but can be trained on any defects you would like to find. This results in lower costs, higher quality inspection reports, and happier inspectors.

Do you want to know more about industrial inspections, please Contact us!